EPDM O-gyűrű

The o-ring is a double-acting sealing element. The sealing effect is achieved by deformation of the round profile of the o-ring. The size of the deformation is determined by the groove depth. The deformation, which is sometimes called also depression or pre-tension, acts in radial or axial direction and provides the o-ring with the initial sealing ability. Under pressure, the o-ring behaves similarly as a liquid with high surface tension. The pressure is uniformly transferred in all directions. The force raised by the initial deformation of the o-ring is added to the force raised by the pressure in the system and they together create the resulting sealing force.

- it may be used as the single and double acting solutions due to its symmetrical diameter

- simple groove decreases costs for design and production

- compact shape enables lower built-up

- simple and reliable installation, incorrect assembly is not possible

- it inexpensive and enables cost-effective solutions

- usability for wide range of static and dynamic sealing applications

- wide choice of mixtures for compatibility with most of the liquids

- with radial compression, e.g. for cocks, valves, hydraulic cylinders

- with axial compression, e.g. flange joints, lids, hydraulic elements

- For dynamic applications, the o-rings are recommended only for mild operating conditions.

| Material | Code |

| EPDM |

OPERATING CONTITIONS

| Temperature | -50 °C +120 °C |

| Pressure | ≤160 bar |

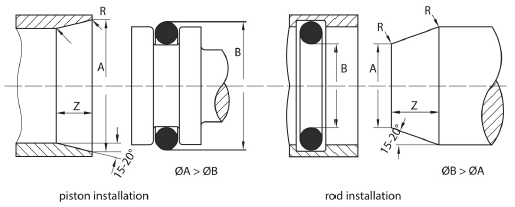

SURFACE ROUGHNESS

| Dynamic | Piston | ≤4 μm |

| Rod | ≤2 μm | |

| Groove base | ≤6-12 μm | |

| Groove flanks | ≤25 μm | |

| Static | Sliding surface | ≤10 μm |

| Groove base | ≤25 μm |

Szeretne többet megtudni a termékről?

E-mail

info@intramark.hu

Telefon

+36 52 540 555

+36 20 913 4498

Nyitvatartás

H-CS: 8:00 – 16:30

P: 8:00 – 16:00

Intramark Kft. központ

4031 Debrecen,

Köntösgát sor 10.